NANGLUONG VIETNAM – Combined Heat and Power (CHP) will thrive as the world races to transition to more efficient, lower-emission energy. This is a proven multitasking tool that generates power on-site using different technologies and fuels. Experts of Vietnam Energy Magazine summarize the latest information related to this technology.

1. Some details about CHP technology:

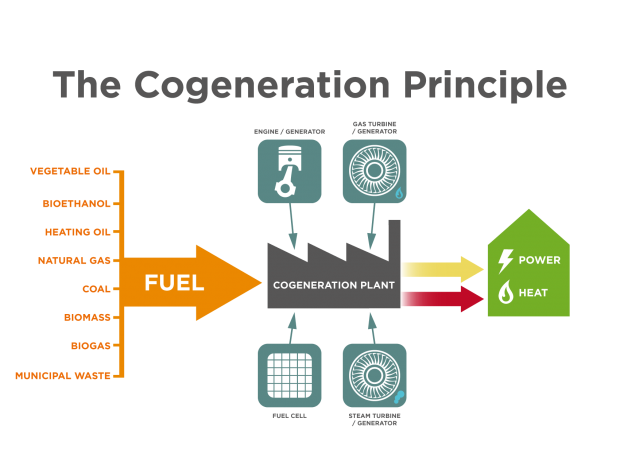

CHP (Combined Heat and Power) can be understood as cogeneration, also known as combined thermal power, which is the use of a heat engine, or an electric machine to generate both electricity and useful heat at the same time. All power plants emit a certain amount of heat during power generation. If not utilized, excess heat can be discharged into the natural environment.

|

| CHP technology flowchart. |

CHP usually has medium and small capacity, which has been applied by many countries in the world in light industry plants, food industry since the 1950s, is a technology to convert energy from biomass waste sources (CHP). bagasse, rice husk, sawdust, wood chips…) to provide power to run the boiler, then the steam from the boiler is used to run turbines to generate electricity.

Part of the steam, after leaving the generator turbine, still has a part of heat energy that will be used to provide heat for heat-consuming households (for cooking, fireplaces, etc.) to serve industrial purposes. CHP’s dual-energy production provides high energy efficiency, which can achieve total system efficiency of over 80%.

CHPs can vary in size, meeting distributed, or fixed energy requirements for end-users such as: Hospitals, schools, hotels, nursing homes, office buildings, or common areas. homes, as well as for larger energy systems, microgrids, factories and other industries, and even power plants. CHPs are highly reliable and heat-recovery, capable of producing heat and electricity 24 hours a day, operating independently of the grid, or deployed with black-start capability to provide a reliable system. reliable, cost-effective alternative to backup generator installations.

Thanks to these attributes, the technology has gained wide adoption worldwide, growing by 30% from 2009 to 2019. According to COGEN World Coalition (CWC): Output of CHP systems in 2019 is 11,200 TWh of heat and 4,159 TWh of electricity, accounting for more than 15% of total electricity production. But this market share is “staggered” by region, decreasing in the context of increasing demand.

2. Situation of CHP in the world and in Vietnam:

By CWC: Representing the major combined heat and power (CHP) companies, the world’s most developed markets for CHP technology are concentrated in Asia-Pacific, Europe, the Americas, and To a lesser extent in Africa, Australia.

In 2019, more than half (59.39%) of CHP systems worldwide relied on coal, as well as coal products, and almost a third (32.28%) relied on natural gas. Less than 1% of CHP plants in the world are powered by peat, shale and oil sands, nuclear energy, geothermal, renewable energy (wind, solar).

While Europe is currently producing 700 TWh of CHP electricity – mainly from steam turbines and combined cycle gas turbines. Europe’s share of CHP, which accounts for 20% of total electricity, has declined, in part due to the energy price crisis. Europe’s CHP plants, led by Germany, run mainly on natural gas, followed by renewable sources such as biofuels and biomass. However, coal still accounts for a large share of Eastern Europe’s CHP production.

The North American CHP market produces about 330 TWh, which is about 6.8% of the total electricity mix. According to the CWC, this ratio has fallen, although the market has been mostly “almost unchanged over the past decade”. Natural gas is the dominant fuel for CHP in the United States and Canada. The Central and South American CHP market is much smaller, producing 87 TWh, 70% dependent on biofuels, including biomass, biogas, waste. Brazil alone accounts for 90% of the region’s total CHP capacity.

The world’s largest CHP market by far is in the Asia-Pacific region (producing nearly 3,000 TWh) – a significant portion of CHP’s global total of 4,000 TWh. Heat production has grown steadily, but 68% of that market is dominated by China, which produces “nearly all” of its CHP power from coal, mainly for heating.

According to the Ebookbkmt news website: The development potential of CHP technology in Vietnam is very large and the prospect because relations between Vietnam and EU countries are increasingly improved, so it is possible to import this technology with initial investment. not high heads from the Netherlands, Finland and Denmark.

In fact, the source of industrial waste in rural areas in Vietnam has not been used much. If with an annual rice production of a few tens of millions of tons of rice, the amount of rice husk discharged from the milling plants can be used to generate electricity up to 757,200 tons, to produce 380 million kWh of electricity.

In the development strategy of the sugar industry in Vietnam, there are about 20 factories with a capacity of over 1,400 tons of sugarcane per day. Accordingly, the capacity of on-site power generation by bagasse is 300 kWh/day (equivalent to the capacity of installing an 80 MW power source), contributing to electricity supply to rural areas.

3. CHP technology prospect:

According to the US Department of Energy (DOE) forecast: After the CHP boom in the late 1990s, manufacturers and developers began to offer standardized, packaged CHP systems built in factory and ready to install, driving a market shift that integrates the commercial, as well as smaller residential markets.

Meanwhile, the economics of CHP have improved dramatically over the past two decades, thanks in part to improvements in turbine and gas engine technology. All equipment manufacturers are working to improve the efficiency, reliability and emission profiles of key engine technologies (including piston engines, gas turbines, microturbines and fuel cells). ).

The emerging potential of this technology is the introduction of CHP Hybrids to suit the decarbonization markets. For its part, the CHP sector will also need to address a multitude of other challenges such as: Ensuring high utilization rates and reliability, efficiency, flexibility, while minimizing capital and infrastructure needs cascade and integration involve carbon-intensive processes.

An emerging solution requires changes to the design and operation of the hybrid system. The optimal combination of solar, storage and CHP can provide “long-term, on-site energy for high-demand sites with the least possible carbon footprint.” Several projects have combined high-temperature renewable energy sources with CHP solutions. For example, the district heating plant Brønderslev Forsyning in Northern Denmark.

According to the DOE: These hybrid systems are a combination of CHP and other distributed energy (DER) sources in one installation. As opposed to a partial DER implementation, the defining feature of a hybrid CHP system is the collaboration between different developers of DER technology (such as CHP, PV and/or energy storage) to Design and optimize combined systems.

“In a typical hybrid configuration with CHP, solar power and energy storage, CHP would be used for electrical and thermal loads, while solar power and storage are used opportunistically to maximize efficiency. maximize renewable energy production and enter the large-scale market for grid services,” said DOE.

However, the main challenge associated with microgrid CHP and hybrid CHP involves forming teams of DER developers and financiers that can deliver multi-technology solutions. The product is complex, and simplified power purchase agreements (PPAs) with no capital investment may be needed to attract end users.

4. Barriers to be overcome and proposed:

According to experts of DOE: CHP has the ability to improve energy efficiency through reducing fuel consumption. However, to ensure the suitability of the CHP system as the transition takes place, the industry will also need to demonstrate a renewable and lower carbon fuel, such as RNG (also known as biomethane). and hydrogen, which can serve as the main fuel source for the CHP system. The United States-based Combined Heat and Power Alliance (CHPA), which works to expand the CHP market is confident that: The industry can achieve this as long as significant barriers are involved in production. The production, transport and storage of “clean” hydrogen is solved.

The CHPA has shown industry-wide benefits to using hydrogen in CHP – or “CHP 2.0”. As well as allowing CHP systems to “reduce emissions further in the industrial, commercial and urban sectors”, CHP systems can use these fuels efficiently.

In addition, as a distributed resource, the use of hydrogen in CHP will promote renewable energy integration, microgrid deployment, and energy storage, as well as adapting to the mix. hydrogen in the gas infrastructure.

The CHPA Alliance notes that: Existing and newly installed CHP systems have used volumes of hydrogen fuel mixtures between 20% and 100%. “The new CHP systems will be capable of burning 100% clean hydrogen. Existing CHP systems, including those being installed today, can be converted to 100% hydrogen at a reasonable cost. These conversions are possible despite the fact that CHP systems in the United States vary widely in application, design, and size.

To date, the overall impact and cost-effectiveness of using hydrogen in larger installations is still being studied.

For example, Siemens Energy is evaluating the economics of hydrogen CHP at Duke Energy’s 14.3 MW electric/33 MW thermal SGT-400 Clemson CHP system at Clemson University in South Carolina.

In 2012, a 160 kW pilot Agenitor 306 CHP system manufactured by German CHP technology company 2G Energy at Berlin Brandenburg Airport demonstrated the combustion of 100% hydrogen and since then 2G has operated 100% hydrogen piston engine models at three other locations in Germany, one in Scotland and one in Japan.

In mid-2023, 2G will begin operating the first hydrogen CHP project in North America at an Enbridge Gas facility in Markham, Ontario.

The CHPA Alliance hopes the barriers to hydrogen will be resolved soon. For the shorter-term prospects, the CHPA points to biogas and RNG, commercial fuels that “can be deployed immediately.” While CHP systems have long used digesters and biogas as fuel sources, agricultural and food waste treatment facilities are becoming emerging sources of biogas production. Meanwhile, RNG can be generated from gasification, or direct pyrolysis of biomass.

“RNG’s high methane content allows for full compatibility in natural gas equipment and pipeline systems. Natural gas-powered CHP systems require minimal upgrades to be fueled by RNG and will produce immediate emissions reductions by conversion,” notes CHPA. However, the CHPA also admits: Raw materials for low-carbon alternative fuels are “relatively lacking”.

In terms of the market, growth opportunities (including the outgrowth of PPA contracts) can be designed to buy both heat and electricity. This contract allows developers to own, operate, and maintain the system, and allows commercial, or smaller facility owners to benefit from the multitude of benefits of CHP without the need for additional fees. committed to maintaining energy sources.

KHAC NAM – VIETNAM ENERGY MAGAZINE SPECIALIST

Source: POWERMAG – 3/2023